Press Release

Hyundai E&C undertakes full-fledged digital transformation by developing ‘Smart Construction Management Platform’

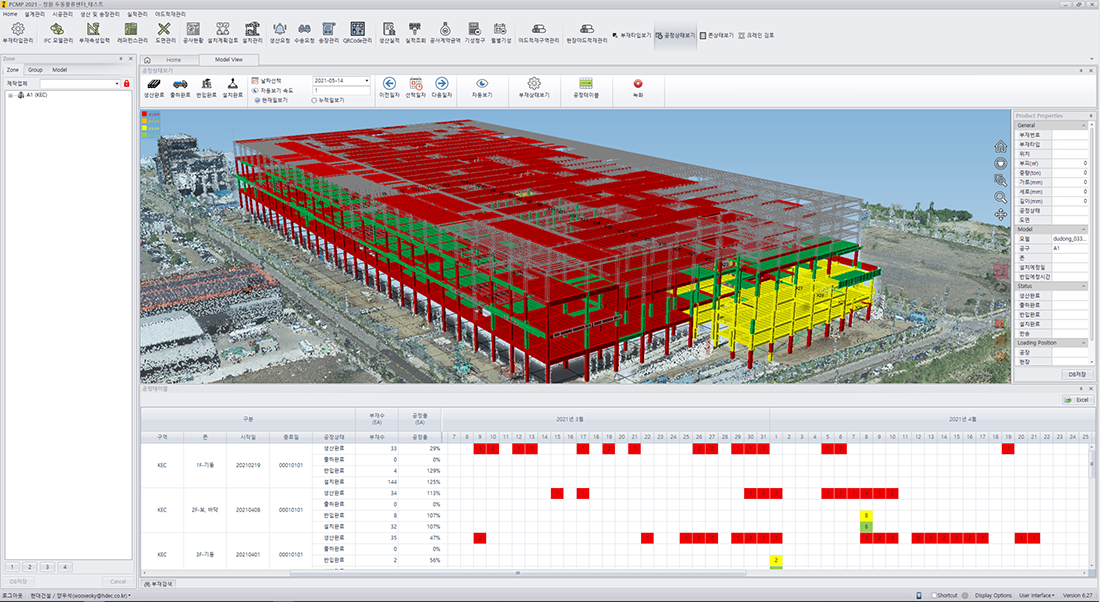

▲ Data tracking and management of the entire construction process (design, production, carry-in, construction) based on BIM

▲ Real-time on-site monitoring using mobile and tablet PCs regardless of location and time

▲ Precast concrete (PC) construction management in the first stage of development with verification completed and application planned for all sites

▲ Improving quality and productivity by actively introducing smart technologies in line with the 4th industrial revolution

Hyundai E&C has jointly developed ‘Smart Construction Management Platform(SCMP)’ based on 3D BIM with software developer ‘Engsoft’. By applying the Smart Construction Management Platform, it is possible to manage the material status of the entire construction process based on 3D data. By using the 3D element technology such as quantity calculation and location identification of construction materials, Hyundai E&C is expected to rapidly quantify and manage related data at once.

Smart Construction Management Platform is a real-time management system specialized for sites that change in real time. By using the platform, it is possible to quickly manage the current status using mobile and tablet PCs, facilitate on-site operation even in complex construction, unclear working environment, and frequent design changes.

The newly-developed Smart Construction Management Platform is specialized in *Precast Concrete (PC) construction material management in the first phase. By tracking the location of 'concrete PC materials' in real time, it is possible to simulate the process sequence and intuitively review and identify the current status.

* Precast Concrete (PC) Method whereby reinforced concrete materials are pre-fabricated, cured and finalized into precast products to be constructed on site.

Hyundai E&C successfully completed the pilot application of ‘Smart Construction Management Platform’ to ‘LH Hillstate Hoam’ and ‘Coupang Daegu Logistics Center’ sites last year and is expanding its application to logistics center sites such as ‘Changwon Dudong Logistics Center’.

The second-phase development of the ‘Smart Construction Management Platform’ is focused on material management for steel construction. In the future, Hyundai E&C plans to expand application to all projects after passing the second-phase application test in ‘Gasan Public Hyundai Knowledge Industry Center’.

Hyundai E&C plans to utilize the digital construction management platform for more precise design and safer construction, by accumulating big data generated for each project. Ultimately, the goal is to establish an automation environment for design and construction. An official from Hyundai E&C said, “It is expected that the newly-developed smart construction management platform will make innovative construction material management possible. Going forward, we will continue to actively introduce smart technologies in line with the 4th industrial revolution to deliver top quality and productivity.”

-

- Family-friendly certified company

-

- Dow Jones Sustainability Indices(DJSI)

- Construction·Engineering leader for 9 consecutive years

DJSI World for 15 consecutive years(2010-2025)

-

- Korea Institute of Corporate Governance and Sustainability(KCGS)

- Total rating A for 7 consecutive years(2018~2024)

Governance(B+), Social(A), Environmental(A)(2024)

-

- UN Global Compact(UNGC)

-

- Science Based Targets Initiative(SBTi)

-

- Carbon Disclosure Project

(CDP, Carbon Disclosure Project) - Hall of Fame for 7 consecutive years(2018~2024)

- 4 consecutive years (2021~2024) Platinum Club (highest ranking)

- Carbon Disclosure Project

-

- Red Dot · iF Award · IDEA Award

- Winning the ‘Grand Slam’ of the World's Top Three Design Awards

-

- Task Force on Climate-Related Financial Disclosures(TCFD)